Register to get 1 free article

Reveal the article below by registering for our email newsletter.

Want unlimited access? View Plans

Already have an account? Sign in

There have been great technological changes in the casting industry in recent years. After the latest announcement of 3D printing jewellery by Argos, and the introduction of laser-sintering machines that ‘print’ jewellery directly in precious metal, TOM DAVIS looks at where the industry is heading

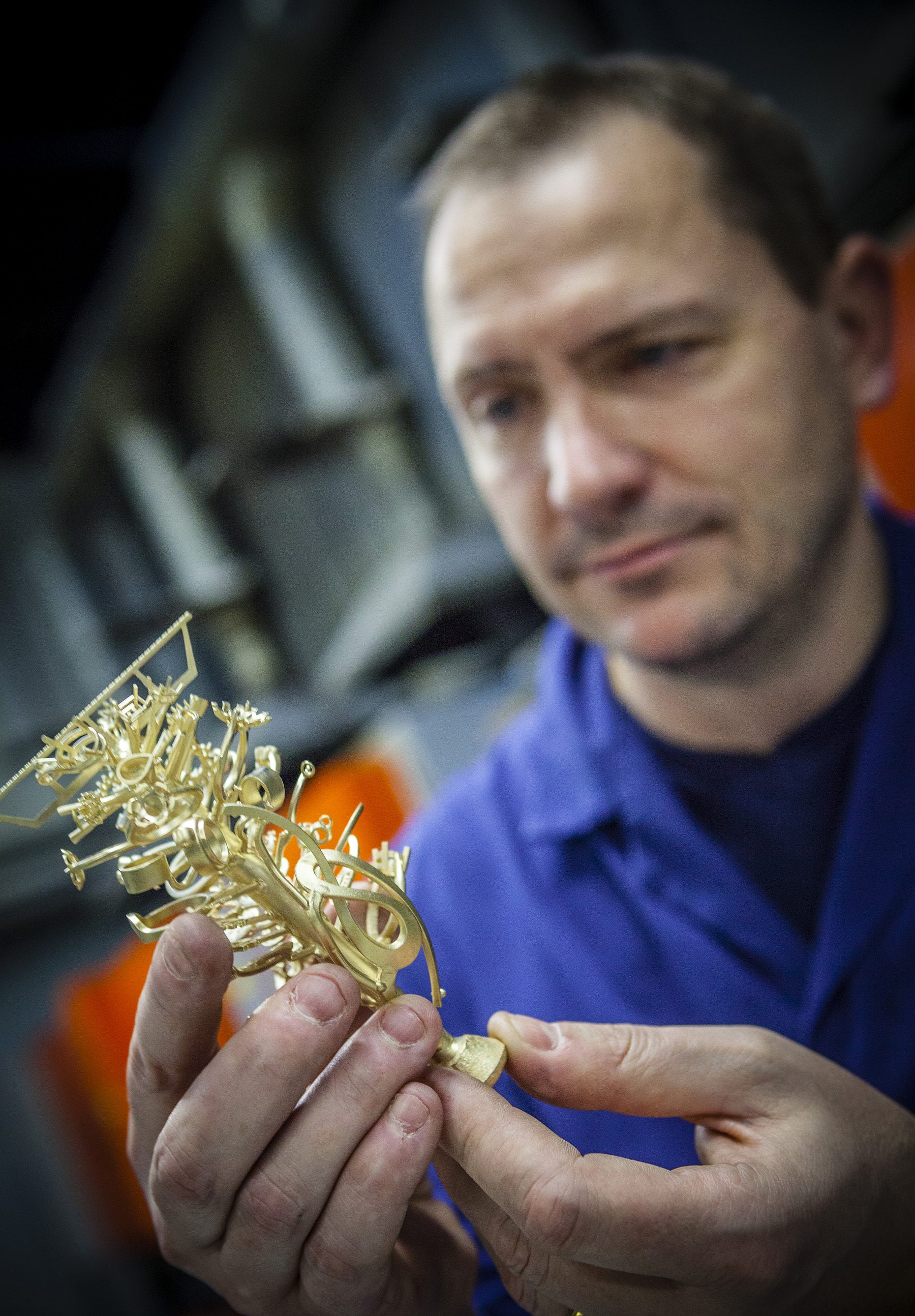

[dropcap]I[/dropcap]n recent years the casting industry has progressed and developed dramatically, particularly due to technological innovations such as computer-aided design and manufacturing(CAD/CAM) technology and 3D-printing. While still in the early stage, this progression has moved one step further with Cooksongold officially debuting its new ‘direct metal laser sintering’ (DMLS) machine, which 3D prints gold jewellery whole, at Baselworld last month.

Casting is an ancient industry, believed to be around 6,000 years old, and while techniques are changing with new technologies, it was not until with the advent of CAD/CAM and 3D printing that the fundamental techniques and processes changed in any meaningful way.

Recent years

The Cooksongold laser sintering machine, which uses gold particles to create complete pieces of jewellery, is just one of many developments in the casting industry in recent years, as CAD/CAM technology and 3D printing has changed the way many casting houses work.

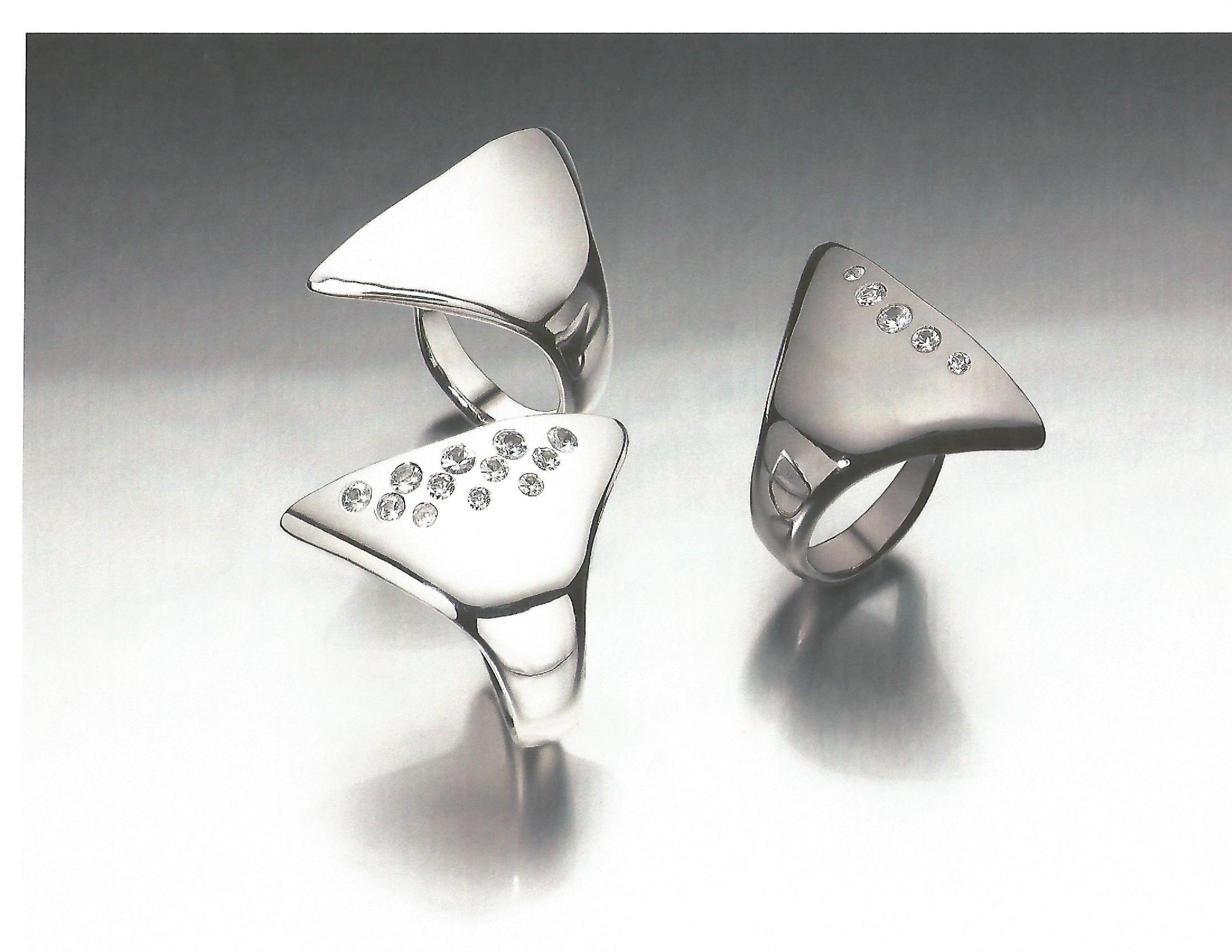

According to Tom Wylie, director at Jewellery Prototyping Services, this new technology is encouraging for smaller jewellers. He says: “The most positive effect I see is the freedom of design now possible and a reduction in labour time and material costs that this technology can equip any jeweller with. It is no longer a sole luxury of large companies but a tool to empower anyone with the imagination to design and make jewellery.”

These developments in technology have also meant there is now a quicker turnaround from idea to development, and the equipment not only cuts down on time consumption but also on cost, benefiting both the retailer and caster. Graham Dicks, director at GVUK, the UK distributor of Gemvision and Envisiontec says: “CAD continues to develop and bring smarter tools, which aid speed and cost savings, and if you can design something in a shorter period of time with more accuracy then that’s got to be effective for your business.” In fact, in much the same vein as major manufacturers, supermarkets and construction firms have been using it for years, Karl Bakker of ABT Design, says ‘just-in-time’ is becoming a viable way to work and giving increased flexibility.

However even these developments are not all great news for casting houses. CAD has created a new type of design which has made it difficult to produce good moulds, with some designs not taking into account the layers required. Apple Nooten-Boom, managing director of Hean Studio, says: “CAD designers don’t always understand the manufacturing processes that their designs need to be subjected to and the constraints and the problems that can cause. One of the biggest issues is that they will do complete, complex, items in one hit. You can’t clean it up and polish it properly because you can’t access all areas because of the enclosed nooks and crannies.”

Mike Hurst, managing director at Jewellery Casting Scotland added that: “We are finding many beginners think that they can design online, get the piece cast, and that’s it. They have no concept of finishing, polishing and s

oldering. This is enabling many amateurs to creep into the jewellery market without proper skills. This can present a real problem to casters.”

Is laser sintering a threat?

Laser sintering is a progressive step for casting, and like 3D printing, many feel it is something that can work hand-in-hand with traditional casting. Despite this, there is an attitude in the industry that the finished product is not yet ready for the mass market. Nooten-Boom believes that one day the two can work hand-in-hand: “Laser sintering is a wonderful new technology which definitely has scope, but I don’t see it as a replacement for casting. Firstly the technology is very expensive, then you’ve got to hold large quantities of finely powdered precious metal and every time you want a different colour or grade you have to clean out the machine or swap everything over. Then there is the cost which is a lot more expensive than casting. But there are applications where it suits, and where casting would not be suited.”

Glen Day, business manager at Weston Beamor, believes that the future of casting could one day go down the laser sintering route. He says: “Print technology now has really caught up with the casting process, 3D printing is at a stage where it can’t get much finer, but it can get much quicker which would be a bonus. The casting process is, in terms of surface finish, the furthest as it possibly can be. What I would imagine eventually, but this is a long way off, perhaps 10, 20 or 25 years, is that you would laser sinter everything together rather than cast it.”

The future of casting

The future of casting will likely include the use of various tools including modern technology CAD/CAM, 3D printing and laser sintering and more traditional methods. The future for the UK casting industry is to likely be in the bespoke market, where there has been particular growth. With lower costs for mass manufacturing in the Far East, the bespoke casting industry in the UK is increasing in size. Alan Factor, customer support at Quality Castings, says: “It’s a niche market and we can turn things around much faster than if people go abroad, even if they are going abroad for their big runs, their prototypes can be turned around here in two or three days. We can’t keep up with the high volumes because we can’t cope with the very low costings abroad.”

“There will always be a demand and a requirement for casting.”

As laser sintering technology improves there is little doubt from those in the know that many casting houses will begin to find ways of using it in the years to come. However, casting is a timeless industry which has near perfected its techniques, and it is difficult to see laser sintering simply pushing it aside. Instead the two industries, one day, seem likely to work hand-in-hand. Leo Onoufriou, director at Just Castings, says: “There will always be a demand and a requirement for casting, it is an ancient method but it is the most effective method of replicating and mass production. There is a good a future for it, as with metal sintering and CAD/CAM, you have to be able to adapt your design to the best method possible.”