ArtCAM helps re-create the Cheapside Hoard

Register to get 1 free article

Reveal the article below by registering for our email newsletter.

Want unlimited access? View Plans

Already have an account? Sign in

State-of-the-art equipment and technology was employed to find out which methods could have been used to create the pieces that make up the Cheapside Hoard; some of which are currently on display at the Museum of London.

Research fellow at JIIC and BIAD Dr Ann-Marie Carey said: “When we received photographs of the Cheapside Hoard, we were fascinated with the level of detail in the jewellery. We started to ask ourselves how such pieces were made to understand the story behind them. Until now, there had been little research into the craftsmanship involved.”

Dr Carey worked alongside senior CAD/CAM technologist at JIIC and BIAD Keith Adcock, and senior curator of Medieval and post-Medieval collections at the Museum of London Hazel Forsyth for several days, taking photographs and scans of the items for analysis.

It was found that some of the collection had suffered deterioration over the years, meaning that the team would have to visualise how the pieces would have previously looked before determining how they were created.

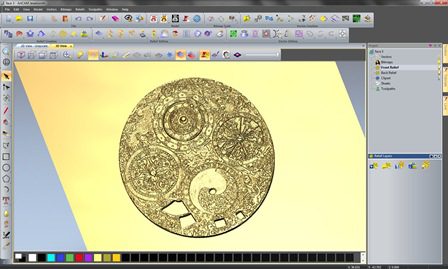

One piece of the hoard suffering considerable corrosion that could not be easily laser scanned was the gild brass verge watch signed by G Ferlite. Keith Adcock explained: “Laser scanners do not work well with shiny objects such as gemstones, glassware and polished gold. For us to accurately scan the Ferlite watch we would have had to chip out the enamel and spray it white, which obviously we weren’t going to do. Nonetheless we scanned the dial of the watch but it needed CAD interpretation and enhancement.”

The watch face was recreated with artistic computer-aided design and computer-aided manufacturing (CAD/CAM) software, ArtCAM JewelSmith. Using this software, from Delcam, Keith imported a photograph of the watch face and used the built-in programme to create a model surface. “ArtCAM is absolutely fabulous for interpreting photographs and creating textures,” Keith added.

Effects of corrosion on the day dial saw Keith employ ArtCAM’s vector drawing tools, shape editor and smoothing tools before ArtCAM rendered the piece as it would have looked before receiving its enamel finish.

Keith then 3D printed the model after remodelling the 3D shapes and creating the necessary files using ArtCAM’s advanced STL Creation. Keith concluded: “ArtCAM was a vital tool in our project.”