Jewellery that changes its colour could be next step

Register to get 1 free article

Reveal the article below by registering for our email newsletter.

Want unlimited access? View Plans

Already have an account? Sign in

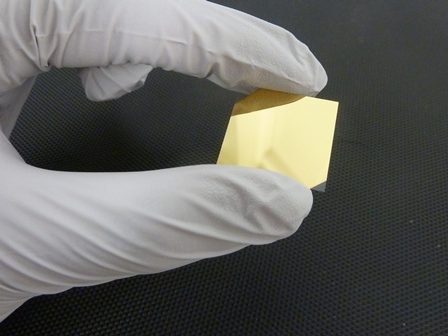

The technology revolves around moulding tiny raised or indented patterns onto the surface of the metal, allowing it to appear a different colour to the human eye, due to the absorption and reflection of light.

The pioneering technology is the first of its kind, according to project leader Professor Nikolay Zheludev.

“This is the first time the visible colour of metal has been changed in this way,” said the professor, who is deputy director of Southampton’s Optoelectronics Research Centre.

“The colours of the objects we see all around us are determined by the way light interacts with those objects. For instance, an object that reflects red light but absorbs other wavelengths will appear red to the human eye.”

The research is equally applicable to other metals such as silver. The breakthrough opens up the prospect of colouring metals without having to coat or chemically treat them.

“This is the fundamental principle we have exploited in this project. By embossing metals with patterns only around 100 nanometres across, we’ve found that we can control which wavelengths of light the metal absorbs and which it reflects,” added the project leader.

The precise shape and height or depth of the patterns determine exactly how light behaves when it strikes the metal and therefore what colour is created. The technique can be used to produce a wide range of colours on a given metal.

The research opens up possibilities of multi-coloured jewellery. A silver ring could be decorated with a number of different patterns, making one part of it appear red, another part green, and so on.

Metal features with sophisticated optical properties that would be almost impossible to imitate could be incorporated into documents as security features.

The concept may be scaled for industrial production using such processes as nano-imprint, whereby large areas are stamped out from a master template in a manner comparable to CD and DVD production, so ownership of the technology could prove valuable.

“We’ve filed a patent application to cover our work,” said Professor Zheludev. “We’re currently talking to a number of organisations about taking our breakthrough towards commercialisation.”