Brand Q&A: AG Mounts

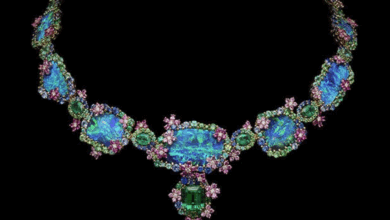

Each process of designing a piece of jewellery is often outsourced from various companies, but not for AG Mounts. We sit down with owner and director, Adam Georgiou, to learn how the company builds each piece of jewellery in house.

Register to get 1 free article

Reveal the article below by registering for our email newsletter.

Want unlimited access? View Plans

Already have an account? Sign in

How was AG Mounts founded?

I established the company in 1996. We manufacture and design jewellery ourselves in our factory. We pretty much do everything from a to z. That includes designing, making, casting, mounting, setting and polishing. We design our own mounts as well, and we take special orders for bespoke pieces of jewellery.

What type of jewellery does the company manufacture?

The jewellery we create is predominantly fine jewellery, mainly in 18ct gold and platinum. We design these with diamonds and precious and semi-precious stones. We design engagement rings, wedding bands, eternity bands and a huge range of jewellery. This ranges from earrings to pendants and bracelets – pretty much everything you could possibly think of.

How can retailers find the products you supply?

We are currently building our website where retailers will be able to view our products, and that is nearly ready. It’s called agmounts.co.uk, and that will show the range of products that we have already designed.

How does the bespoke service work?

Jewellery retailers can come to us with a picture, or their own ideas for a jewellery piece, we will then create a drawing using a computer-aided design program called Matrix. Then we will send it back to the client and work with them on alterations and work to meet their specifications, after that we have a 3D printer and we use a mould to print the jewellery into a model. We then build that up for casting and we have two types of machines for gold and platinum. Once the piece has been cast we then take it to our mounting room and the guys there work on it, refine it, assemble it and then it goes to our setting room. The setting is done very professionally with only microscopes for all types of settings. It then finally goes to polishing, so the whole process is done in-house.

Doing the whole process in-house must be quite unique?

Yes, there isn’t another workshop in Hatton Garden where they do everything in one place. Sometimes they will take the setting out, or the mounting, but the casting they almost definitely will take to an external company.

Could you give us a scale of the company?

When you create fine jewellery you don’t need to have a massive company with lots of people working for you. We have three mounters, two polishers, one caster and also people working in the showroom. In total we have 10 people working for the company.

What’s the design process for AG Mounts own range of jewellery?

The main designer is myself – when I make a ring I will make it in two different types of settings, so I will alternate it and just by changing one detail we can create a completely different style of ring. I spend a lot of my time coming up with new designs that we can create in house.

What kind of materials do you work with?

Metal wise we work with 18ct white, yellow and rose gold, as well as platinum and palladium. We do silver as well but we try not to work with that as much as our specialty is in very fine metals and jewellery pieces.

How can working with AG Mounts benefit the jewellery retailer?

If the retailer is providing a large diamond and they want to be secure, they will know that the diamond they provide will come here and never leave our office until they collect it. This is because we do everything in house. Secondly, we are a UK manufacturer and that’s much better than the quality from Far East manufacturers. We guarantee the setting and that the stone will not fall out, we can also guarantee that our quality of jewellery making is incredibly high. We are also competitive with our pricing, and the fact we do it all in house helps to keep those prices down.

Do you have any new initiatives you are working on?

Any design we make now, we animate. That means that retailers won’t just have pictures on their websites, they will have animations of the products they buy from us. The retailers can have their logos on the animations of the products and they can visit our website and choose more animations to add to their website for a certain cost. This is something completely new we are doing and we will release it to the trade soon. Not only are we selling them the product but we are also helping the retailer market it to their end consumer. The animation shows all of the angles of the piece and it’s a very clear representation. It coincides with the rise of ecommerce and gives them another market to sell into.

How has the market been over the past 12 months?

Brexit and the current state of the economy has affected us because we are working in a luxury industry, it’s not something that consumers necessarily need. I think the whole of the industry isn’t performing quite as good as it was previously. We have noticed the increase in gold price as well as the dollar exchange rate, but we are still busy and that’s always a good sign.

What styles are currently on-trend?

We have mainly noticed that engagement rings and eternity bands are very popular right now, we specialise in these products and they are our best sellers.

How many UK retailers do you currently work with?

We create around 200 new mounts each week and we are working with 200 retail jewellers across the UK market.

What do you see the company, in say, five years time?

We have some big plans at the moment, and we are working on them to become one of the best in the industry. In five years time I see AG Mounts as one of the biggest bespoke manufacturers in the UK.

This feature first appeared in the April 2017 issue of Jewellery Focus.