Register to get 5 free articles

Reveal the article below by registering for our email newsletter.

Want unlimited access? View Plans

Already have an account? Sign in

In the third instalment of his series about the ‘Changing Face of Contemporary Jewellery’, JACK MEYER explores the new potential business models and opportunities opened up by recent advances in e-commerce and 3D printing.[divider style=”solid” top=”20″ bottom=”20″]

Recently I read a pair of articles from InStore Magazine, wherein the writer wondered whether we are seeing the death of the high street jewellery store. Given how millennial shoppers have demonstrated a greater likelihood of spending their discretionary income on an iPad than a necklace, and how an ever growing share of retail business is happening online, they pondered what it would take to stay relevant in this new era of giant luxury brands and online commerce. In this very magazine last month, editor Michael Northcott urged us all to maintain a positive outlook and to start exploring e-commerce.

But surely all is not bad news for retailers. As I mentioned in my previous articles, new opportunities appear with the changing of the times to replace the old ones. So with the new increasingly digital economy, where can we find these opportunities?

SOME GOOD NEWS FROM ALL THE CHANGE

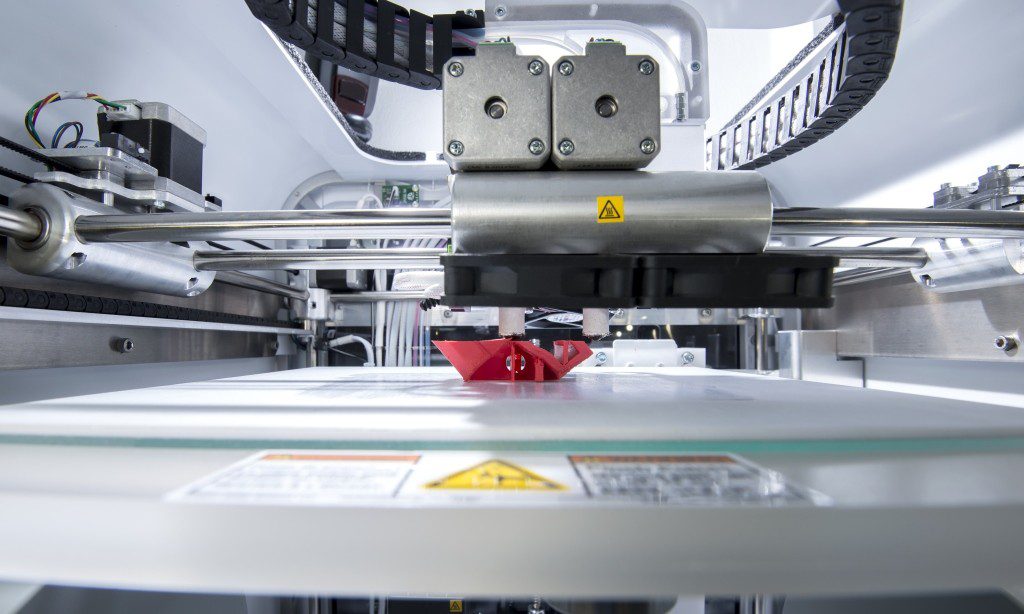

We all already know by now how much 3D printing has affected the way business is done.

The CEO of Autodesk recently said he thought “the idea of home 3D printing is overhyped”. While I partially agree, a good response to this would be something James Dyson once said: “People have a tendency to overestimate the importance of a new technology in the short term, but underestimate it in the long term.”

But even setting that aside, the effect that 3D printing is having on the industrial marketplace and in product design is hard to overstate nowadays. A new report recently compiled by SmarTech’s Scott Dunham predicted that the market for precious metal 3D printed components is set to grow to £4.1 billion by 2024. Or to look at it from another angle, 3Dhubs keeps a registry of home hobbyist 3D printers who offer “build time” on their machines to anyone who wants to pay for it.

As of August 2015 there are currently over 20,000 registered home 3D printers in their community. But no matter how you look at it, there is an awful lot of demand already for 3D printers, even among home users. And all indicators seem to show this is growing.

With a market growing this quickly, both in industry and with a steadily rising number of home hobbyists, it seems logical to predict the demand for 3D printed content will not only continue grow, but grow at an increasing rate.

Developers of 3D scanners have already been banking on this rapid growth in demand. They have been working very hard for the past decade to improve their scanning machines to the point where the models produced are finally useful for 3D printing. Although 3D scanning may prove an effective way of taking natural objects or used objects into the realm of 3D printing, these machines will never be able to substitute the knowledge, technical expertise and aesthetic discretion of a designer. This means in the near future we will be seeing a strong spike in demand for CAD model content for 3D printing, which will likely only get bigger as more and more homes own 3D printers.

NEW ROUTES TO MARKET IN THE NEW ECONOMY

In short, this brave new world of 3D printing needs designers. Not just in jewellery, but in all areas of product design. As it happens, many of the smartest people working in e-commerce, 3D printing, and education have already seen this problem coming up on the horizon. This has led to a proliferation of very interesting market solutions and new business opportunities that didn’t exist even five years ago.

Here are some we’re already seeing now:

Online Ring Design and Manufacture on Demand

The first opportunity has been available for years already. One of the biggest advantages CAD has offered designers is the opportunity to render and present an object before it has entered manufacturing. One by-product of the recent recession has been jewellers using this technique to present and test market collections that do not yet exist. This has served quite a few jewellers well with selling to the general public, particularly those who are unsure how a certain product may be received.

Taking this a step further would be to offer your entire catalogue online and then manufacture or produce pieces on demand. Gemvision’s and Stuller’s Countersketch Studio banked on this by going so far as to build a semi-bespoke design tool to allow software users to assemble designs from Stuller’s part catalogue in store, and request the piece to be manufactured on demand back at Stuller headquarters.

But you don’t even need to go that far. Stubbs’ ConfigureRing is an already established example of a big jewellery label using a computer-based catalogue to allow clients to choose the ring they want to assemble and order from a catalogue of matched findings. There are many more online ring design tools as well at varying levels of complexity (ranging from 77 Diamonds to Blue Nile).

There are even designers who show their entire catalogue online in CAD, and then produce the pieces on request. Paul Michael Design has made a successful business based on this method of presentation, selling to 30-something gamers and cosplayers.

Online CAD Model Communities and Marketplaces

An extension of this design-first, manufacture-later strategy is the online model community. While CAD models have always been available from various industry online marketplaces (Bermark Design is one well established jewellery model marketplace), the idea of combining a model marketplace with a social network and 3D printing bureau creates an entirely new opportunity for designers.

Thanks to the founding of sites such as Shapeways, i.Materialise, Thingiverse, and Styleshapes, it is now possible for a designer to create CAD models and make them available for purchase by the general public. These can then be used either for 3D modelling or for manufacturing on demand using the host community’s own 3D printing services. The customer gets a part in any material they wish, and the designer gets a royalty payment. It has become an excellent way for designers to make extra money.

Taking this concept to the next level is the newly launched Cadfolio. It uses a social network framework to connect CAD designers, manufacturers, gem dealers, and retailers to provide a more efficient way of doing business and interacting with customers. While it doesn’t open up your work as a catalogue to the general public, it does allow you to share your own catalogue with chosen business associates for their use while simplifying payment transactions.

The New Plastic Jewellers

As 3D printing materials have become more varied and versatile, it seems fashion jewellers and some designer-makers have already started experimenting with using 3D printed materials straight off the machine for small production runs of plastic jewellery. The work of brands like The Rogue + The Wolf, Dyvsign, Electrobloom, and the Laser Girls show the potential 3D printed materials hold as a finished product in itself. While few designers to date have taken the big step into direct manufacturing of precious metal sintered parts, there are already service bureaus providing a metal sintering service for jewellery, so it is only a matter of time…

The Proliferation of Design Contests

Another business model brought about by the internet is the concept of crowdsourcing. The idea is that a customer provides a request for a design, and several designers bid on the design brief in the form of a contest, providing preliminary designs which are then rated, the winning design getting the contract. This model has proven rather popular with graphic design and freelance computer programming. There is even one company called Partumis Metal which provides a crowdsourcing service for blacksmithing and large scale metalwork.

In terms of jewellery, this idea of crowdsourcing has found expression in the form of online CAD jewellery design competitons. At the moment there are two: London-based Gem Prive, and Toronto-based Mejuri. With Gem Prive, designers are given a brief, for which they produce a CAD design, which the general public votes upon and the winner’s design gets put into production.

For those who are new to industry, this can make for an interesting opportunity to gain exposure, especially when you consider the site attracts voters for designs from all over the world.

Patronage and Sponsorship

That’s not to say all the new design contests appearing are online only. More competitions are available than ever to help new designers get noticed. The ECone Unsigned competition, for example, provides recent graduates with an opportunity to be stocked by ECone gallery.

On a grander scale, Stephen Webster has been offering his own patronage scheme called the Rock Vault, which takes up and coming designers and helps them develop their business. Also, the Goldsmiths Company’s Setting Out program focuses on more of the educational and developmental aspects of patronage, investing in the designer’s education rather than their financial backing.

What This Means for Handmade Jewellers

Considering how many of the above opportunities are based upon CAD/CAM, established jewellers could be forgiven for feeling dismayed about the future of handmade manufacturing.

Recently I spoke to Dauvit Alexander about this very issue: “My approach to CAD/CAM has always been very practical – ‘it is another tool’ – and I don’t mean that in a dismissive way; I would say the same of my piercing saw and the new technology has become as central to my practice as the piercing saw which I learned to use at age 14… I have never considered these technologies as anything other than part of an integrated practice, and I think that for small fine jewellers to survive, this is an essential approach both in terms of efficiencies of time and materials but also in terms of being able to raise standards.”

When you consider CAD and 3D printing as not only just ‘tools’, but just two tools out of many in an integrated process of design and manufacturing, this highlights the need for the understanding and insight which only comes with practical hand bench experience.

Adding onto this, it is also worth remembering that the current 3D printing boom was fuelled by the Maker Movement, which in turn was brought about by a growing desire for handmade and do-it-yourself goods in the face of overabundance of cheap imported factory made goods. Indeed, that do-it-yourself mentality common to home 3D printing hobbyists can be seen in an increasingly common phrase they use: “A 3D printer is a project, not a product.”

Bearing all this in mind, it would seem the demand for skilled craftsmanship and making knowledge is greater than ever, even if it is now demanded in new areas and avenues of work.

Conclusion

The jewellery market is shifting. We cannot escape that reality, nor can we deny it. But with that shift come new potential opportunities. In particular, we need not just new CAD designers, but new CAD artisans like never before, and the demand is only going to increase.

[box type=”info” align=”” class=”” width=””]About the Writer

Jack Meyer is Senior CAD Tutor at Holts Academy, and creator of the jewellery technology trends blog CADJewellerySkills.com. Since he started working in Hatton Garden in 2006, he’s been following the changes in opportunities for jewellery industry newcomers, and has been involved in several jewellery sector training initiatives.

Further Reading

Go to www.cadjewelleryskills.com/opportunities/ for a list of all references and links to each of the websites and online communities mentioned in this article.[/box]