Missing opportunities in bespoke manufacturing

Modern manufacturing methods mean that it has never been easier for retailers to offer their customers the choice of having their own bespoke designs created especially for them. Yet many are failing to do so and as a result are missing out on good business opportunities, says Glen Day

Register to get 1 free article

Reveal the article below by registering for our email newsletter.

Want unlimited access? View Plans

Already have an account? Sign in

Time was when many high street retailers would have had their own in-house jewellers who could undertake repairs, alter existing pieces of jewellery to give them a new look or potentially create something completely new and unique for those customers unable to find exactly what they were looking for in stock.

Few retailers today have the luxury of having a jeweller on-site but, thanks to services available to them through companies such as Weston Beamor, this does not preclude them from providing a full bespoke service. Yet, strangely, many seem reluctant to do so and when faced with a customer looking for a specially shaped wedding band to fit around an unusually shaped ring; someone looking for a new design from an antique heirloom; or simply someone looking to have their own design idea brought to reality; will lose the sale rather than seek a solution.

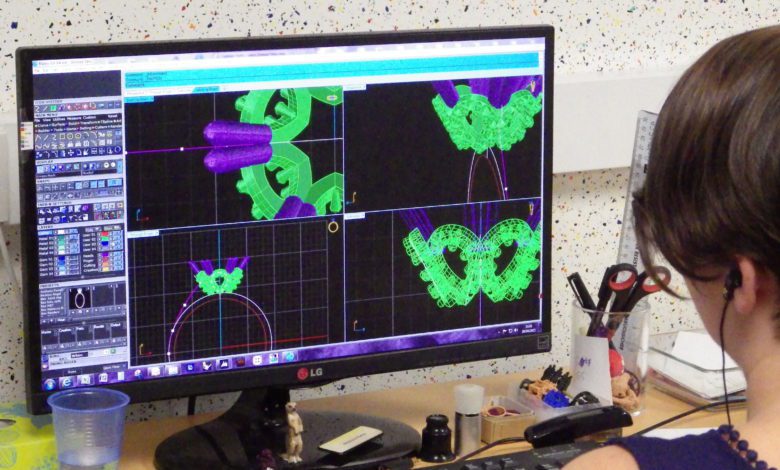

I believe this may well be because some retailers simply don’t understand how straightforward, fast and satisfactory the bespoke manufacturing process can be. They may also be unaware of the latest technologies which allow manufacturers not only to create photo-realistic images of any bespoke design for approval by the customer before any work has actually begun, but also to supply a resin-prototype for customers to see and try on before making their final decision.

Today’s manufacturing processes truly do mean that no retailer is going to be left with a commissioned design that their customer doesn’t like – all potential glitches can be sorted out via email well before the final piece is even made.

Take for example the strangely shaped wedding band. To create a bespoke design to sit alongside a particular engagement ring all that is required is a 3D scan of the ring in question. This can be done in a matter of days simply by sending the band to the bespoke manufacturing company to have it electronically scanned.

Once its dimensions are safely stored in digital form the actual ring can be returned to its owner while the design process takes place. To do this the manufacturer will transfer the ring’s dimensions to a computer aided design program and create an aesthetically-pleasing band, to the owner’s own specifications if desired, to sit snugly against it.

A computer-generated picture of the virtual band design can then be sent to the retailer for approval by the customer before the ring itself is actually made. Should the customer – having seen how the design will look – wish to alter the design, make it wider, add more diamonds, take away some diamonds, change the colour of the gold, or whatever, such changes are very easily made and a revised drawing can be provided.

The brief for a bespoke design can be as detailed as a scale drawing or a computer file and as vague as the proverbial sketch on the back of a fag packet. A competent bespoke service will be able to interpret what is required however the design is supplied to them and will provide a product that your customer will love.

Another great plus of the sophisticated manufacturing systems now used is that they allow the manufacturer to calculate extremely accurately how much precious metal any design will require so you can give your customer a very accurate quote. If something is too expensive it can be trimmed down to meet a specific price point.

Sophisticated bespoke manufacturing also allows retailers to offer their customers pieces designed to fit a particular precious stone. The creation of a 3D resin model, prior to actual production, will ensure that the fit of the stone is absolutely correct and eliminate any possibility of error and the potential loss of the jewel at a later stage.

It is not easy to explain these things in mere words and for the layman the technologies can sound somewhat daunting. However seeing, as they say, is believing and I would urge all retailers not currently making use of a bespoke manufacturing service to check this out and go and have a look at what is available. I guarantee it will help them to improve not simply the service they can offer to their customers but also their bottom line.